Content :-

- Material & Components

- History and Scope

- Size & Wall Thickness

- Standards

- Wall Thickness Design with ASME B31.3

- Length

- End Preparation

- Pipe Manufacturing

- Difference Between Pipe & Tube

- Material

- API 5L

- Pipe Connection.

What is Piping Engineering ?

Piping Engineering course is one-of-a-kind. This course is structured to raise the level of expertise in piping design and to improve the competitiveness in the global markets. This course provides various piping system designs, development skills and knowledge of current trends of plant layout. The students are given case studies to develop their professional approach.

Introduction to :

- Piping Engineering and role of Piping engineer in various fields

- Industry functioning and plant overview

- Function of process equipment and their piping requirement.

Detailed Study of :

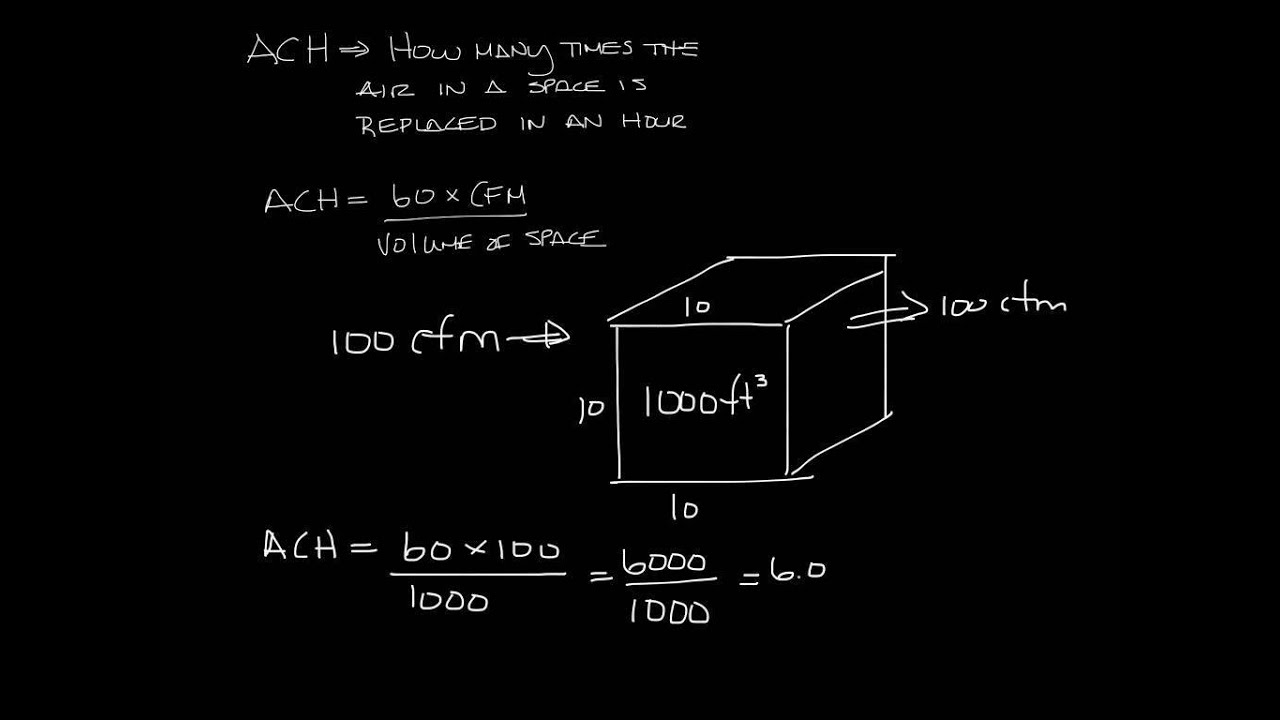

- Various piping system

- Procedure of designing piping system

- Material selection for various process services

- Piping elements, their joining methods

- Relevant standards / Codes, their importance and applications

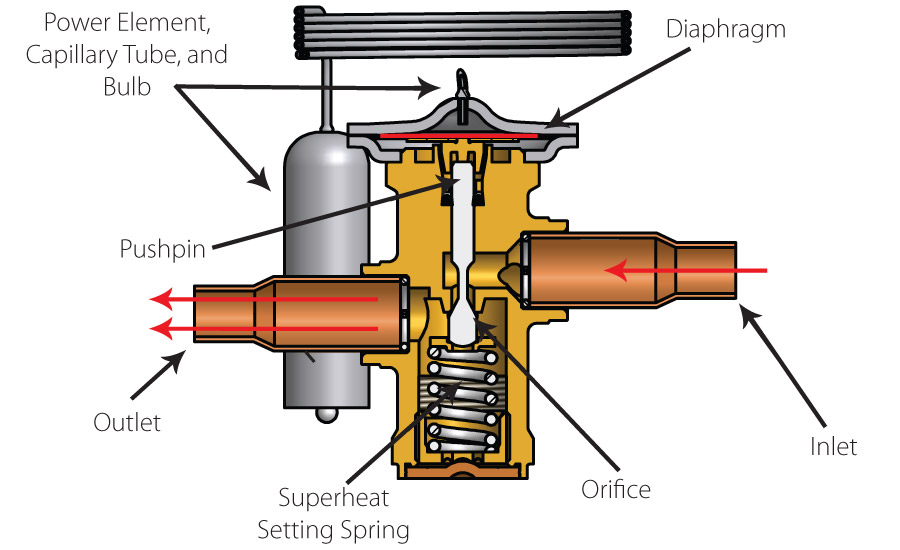

- Valves & Nozzles

Document Study :

- Use of vendor data in design

- Various documents required for plant design

Preparation of :

- Piping material specification

- Valve specification and data sheets

- Nozzle orientation of process equipment

- Bill of Material at various stages

- Isometric drawings and final MTO

- Development of :

- Equipment layout

- Piping layout

- Industrial Plot Plan